VW Type 1, 2 & 3 Engine Main & Rod Bearing Measurements

When rebuilding a VW engine it is crucial to make sure that you install the correct Main Bearings (between the crankshaft and the case) and Rod Bearings (between the connecting rods and the crankshaft). When replacing the main bearings in an engine, you need to know three measurements: the inside diameter (ID) of the main journals on the engine case, the outside diameter (OD) of the crankshaft journals, and the thickness of the thrust surface on the rear bearing journal. Ideally, when you take your VW engine case to your machine shop they can inspect your case, machine it as necessary, and provide measurements for the main journal and the thrust surface. Most will actually stamp the case to indicate what machining has been done. If they don’t, make sure to get that information from them and keep it handy as it will make ordering the correct bearings much easier.

VW Service Manuals use metric (millimeter) measurements and most machine shops in the US will refer to any machine work that has been done with Imperial (inch) measurements. For reference, 0.25mm is the equivalent of 0.010” (ten thousandths). If you take an original, never machined case to a shop for an align bore, they will most likely take it down twenty thousandths. Most shops will then stamp the top of the case ’020’ to note how much material has been removed. We don’t recommend using your old bearings as a reference. They are old and won’t be re-used. You most likely pulled the engine apart because it wasn’t running well, was making an odd noise, or perhaps just to be freshened up. The bearings may have been part of the problem, maybe not. Either way, the bearings can’t be reused, so throw them in the trash. They are no longer part of the equation. Measure the parts that will be used.

Main Bearings - Line Bore Measurement:

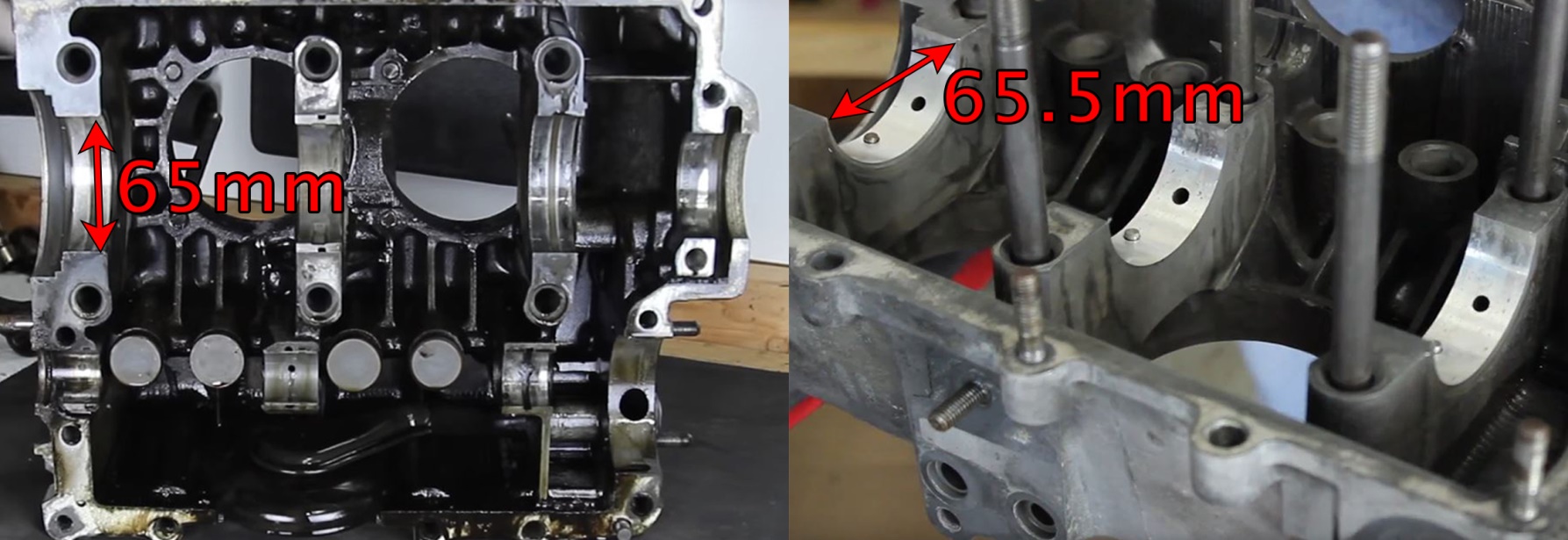

A factory stock engine case for a 1200cc 40 horse single port, a single port 1300, 1500 or 1600cc or a dual port 1600cc engine has a line bore ID of 65mm or 2.560”. For example, when we rebuilt the engine on our 1971 VW Super Beetle our machine shop inspected the case which had never been rebuilt so the factory line bore was still at 65mm. The machine shop align bored the engine .020”, to the first “oversize” (OS) so the line bore was now 2.580” (65.5mm) and we could factor that measurement into getting the correct main bearings for the engine.

This is a pretty straight forward measurement but we do want to note that as the case wears and the bearings need to be thicker there is an inherent loss of oil pressure. There are bearings that are offered for cases machined out to 67mm or .080” over, but we don’t typically recommend rebuilding a case that has been machined past 66mm. We suggest finding a good used case or purchasing a new case if you want a long lasting engine. The 1mm larger than stock bearing rule applies in combination with the crankshaft so keep that in mind when using a machined case and crank. For example a case that has been line bored twice (to 66mm) should not be run with a crank that has been turned even once. The bearing is now 1.25mm thicker than stock.

| Original engine case after disassembly has a factory ID of 65mm. | The same engine case after being align bored 0.020” (.50mm) has an ID of 65.5mm. |

Thrust Bearing - Thrust Cut Measurement:

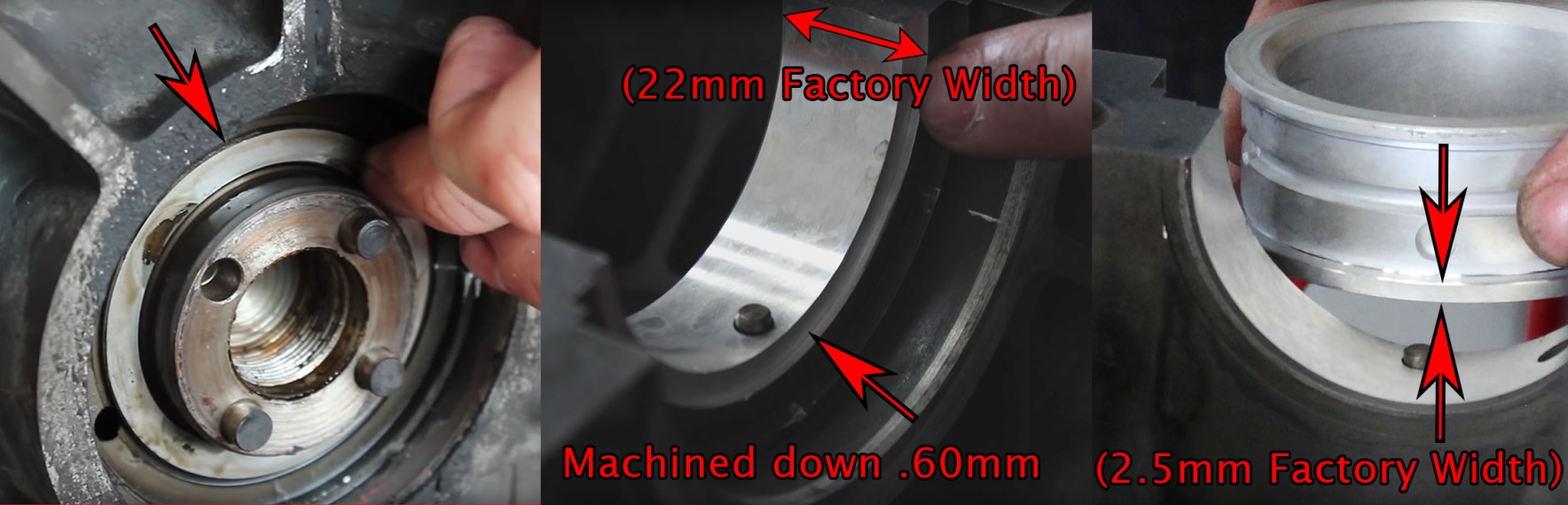

The thrust surface of the VW engine is at the flywheel side main journal. The bearing that sits there, along with the flywheel and flywheel shims, limit how much the crankshaft can move back and forth in the case. The crankshaft should move no more than .006” of an inch, and the bearing should not move at all. If the crank moves more than .006”, the flywheel gland nut isn’t tight, the shims are incorrectly set, or the bearing and case thrust surfaces are worn. If the bearing and case are worn, the crankshaft and bearing will move back and forth in the case more than they should and will cause more wear, and eventually worse issues will develop.

From the factory, the saddle where the thrust main bearing sits measures 22mm (.866”) across. The original main bearing has a 2.5mm thrust shoulder on the thrust surface and a narrow shoulder at the opposite side and sits over the saddle in the case. If your bearing has a thicker shoulder, or the case is narrower than 22mm at the thrust surface you will need an oversized thrust bearing set. Oversized thrust bearings are typically offered in 1 and 2mm OS versions. Generally, machine shops will cut down the engine case at the flywheel side to perfectly match an oversized bearing.

There are two common methods to cutting down the thrust area on the case. The first method is to cut down the case 1mm or 2mm as needed to assure the over the counter replacement OS bearings will be a direct fit. The other method, which takes a bit more work, is to cut down the case just enough to remove the damage, and then machine the inside shoulder of a suitable main bearing (either 1 or 2mm OS) to fit.

This method leaves more material on the case to support the crankshaft and is preferred, but since the main bearing itself has to be machined. The one down side is that you have to know the size of the journals on the crankshaft that will be used, so you have a main bearing set ready to be machined. If your machine shop specializes in air-cooled VWs, they may have a set of main bearings ready. If they aren’t, be prepared to make another trip back to the machine shop once you know what diameter the case is machined out to. Then knowing what the crank the measurements are, you can order a suitable set of bearings and head back to have the shop cut down the thrust bearing accordingly.

| If the bearing behind the flywheel moves, the thrust surface on the engine case needs to be machined down. | The factory saddle measures 22mm across. The step is where the case has been machined down. | A 1mm oversized thrust bearing is machined down 0.40mm at the inner lip upper arrow) to fit tightly at the saddle on the case. |

Main Bearings – Crankshaft Measurement:

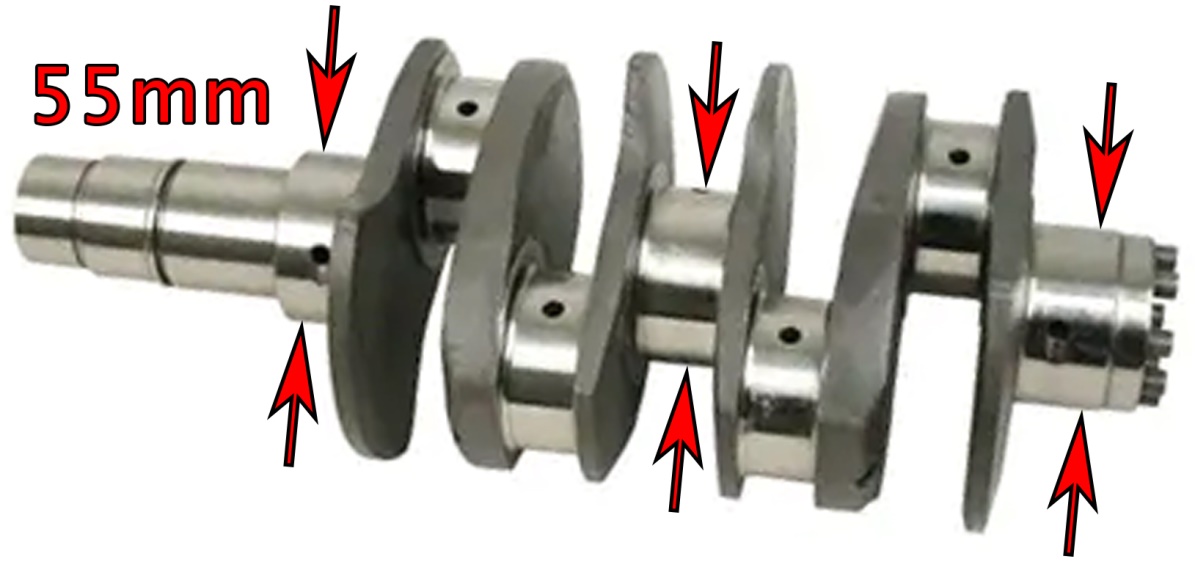

An original factory crankshaft for a 1200cc 40 horse single port, a single port 1300, 1500 or 1600cc or a dual port 1600cc engine has main journals with an OD of 55mm or 2.165”. The main journals are the center journals of the crank and contact surface where the main bearings sit in between the engine case and the crankshaft. If you are rebuilding your VW engine and plan on reusing the crankshaft, take it in with your engine case for inspection and machine work as need. If the shop determines the crank needs machine work it can be turned down to remove minor damage from a seized bearing or overheating.

Because the crankshaft is made of hardened steel, typically less material needs to be removed and machine shops will cut down the crank in .010” (.25mm) steps as needed. So a crank that is cut to the first oversize (technically it is undersize as it is now smaller than stock but in machining purposes we refer to it as oversize) will measure 2.155” or 54.75mm. Oversized main bearings are available for cranks that have been turned down to 54mm, but as we mentioned above, we do not recommend running a main bearing that is anything more than 1mm thicker than stock. Realistically, if a crank has to be turned down more than twice, chances are that it has seen too much use and should be retired.

Selecting Main Bearings:

Using the 3 measurements outlined above, you can select the appropriate sized bearings using the main bearing chart below. We don’t recommend going past the 2nd oversize on the engine case, and would only do so with a new crank. Along those lines we wouldn’t go past a 1st oversized case and a 2nd undersized crank. Engines built past these points have been successfully built and run, these are just our preferences.

(Click image for Size Chart with Clickable Links.)

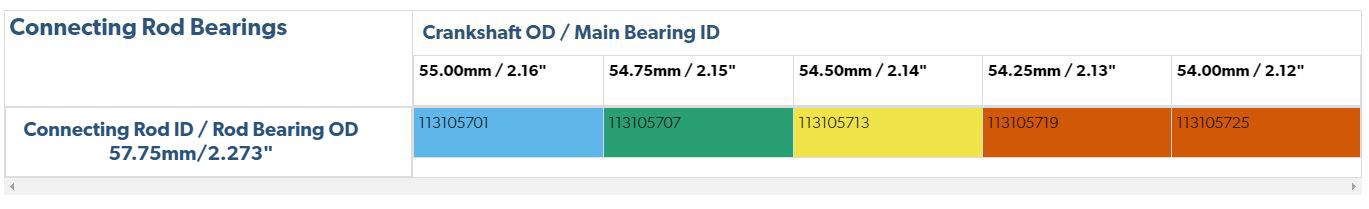

Rod Bearings – Crankshaft Measurement:

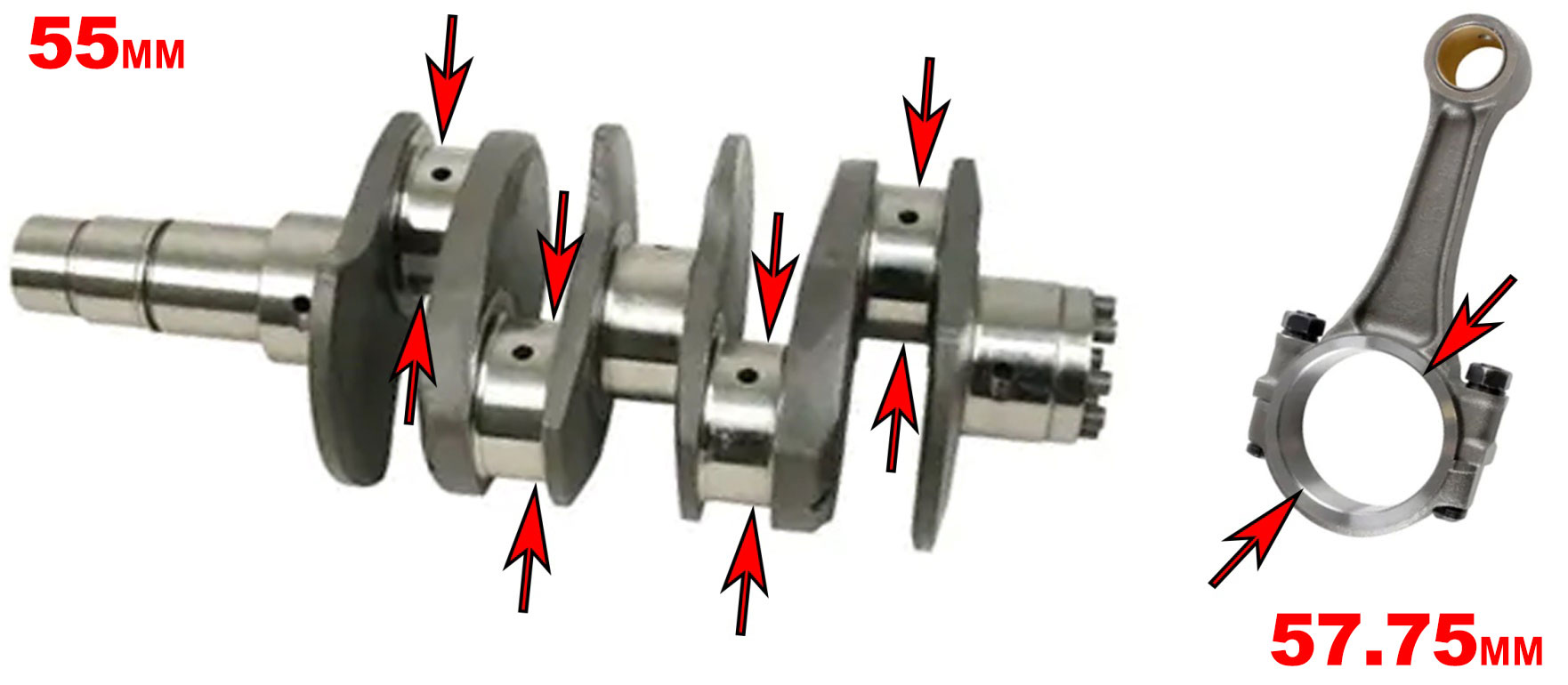

Just like the main bearing journals we covered above, the rod bearing journals on 1200cc 40 horse single port, single port 1300, 1500 or 1600cc and dual port 1600cc engines have rod journals with an OD of 55mm or 2.165”. The rod bearings are available in the stock, 54.75, 54.50 & 54.25mm (2.155, 2.145, & 2.135”) oversized sets. Unlike the main bearings, only the crankshaft is turned down. The connecting rods themselves are not machined past the stock measurement. New and rebuilt VW rods will have an inside diameter of 57.75mm or 2.275”. A crankshaft that has had the rod journals turned down to the second over size will measure out at 54.5mm or 2.145”. Rod bearing thickness isn’t as crucial as main bearing thickness but goes along with our preference that a crank turned down more than 2 times should be retired.

Selecting Rod Bearings:

Selecting the correct rod bearings is much simpler than main bearings. All the VW connecting 40 horse and later engines have a 57.75mm ID, so all you need to know is the OD of the rod journals and you can use the rod bearing chart below to know which bearings are needed. A crankshaft that has been turned down twice (more than .50mm) should be retired. New crankshafts are inexpensive enough and well worth the cost when spending the time and effort building an engine.

(Click image for Size Chart with Clickable Links.)

5-Star Rating!

5-Star Rating!